Achieving operational excellence starts with clearly defined processes, and standard operating procedures (SOPs) help with that. SOPs ensure consistency, quality, and compliance while supporting risk reduction.

Understand with us the essentials of SOP, how to write an effective one and the process we follow at PKC Management Consulting to implement the most effective SOPs.

What is SOP (Standard Operating Procedure)?

A standard operating procedure is a set of step-by-step instructions that describe how to carry out a routine task or procedure within an organization.

SOPs are designed to ensure that everyone in the organization follows the same process, resulting in minimal errors and inconsistencies.

SOP is used in a wide range of industries, including manufacturing, healthcare, IT, hospitality, and more.

A standard operating procedure can take different forms depending on the needs and requirements of a business. Here are some common forms of SOPs:

Common Types of Standard Operating Procedures

- Step-by-Step SOP: Provides a detailed, chronological sequence of steps that employees must follow to complete a task or process. Can include specific instructions, tools needed, and safety precautions.

- Hierarchical SOP: Breaks down a procedure into a series of sub-procedures, each with its own set of steps.

- Flowchart SOPs: Makes use of graphical symbols and arrows to represent the sequence of steps involved in a process. They are easy to read and understand and are ideal for procedures that involve multiple paths and decision points.

How to Write an Effective Standard Operating Procedure (SOP)?

SOP writing requires a well planned approach. Here are our recommendations to writing the most effective SOP for business:

- Define Purpose, Scope, and Compliance Objectives

- Clearly state the SOP’s goal and align it with organizational and regulatory requirements such as FSSAI for food safety or UGC for education.

- Specify departments, locations, or regional applicability, considering diverse state laws like labor laws.

- Integrate Indian legal frameworks (GST, Companies Act 2013, Data Protection Bill) and industry standards (NABH for healthcare).

- Involve Stakeholders with Cultural Sensitivity

- Engage local managers and team leaders to address ground realities.

- Respect hierarchical structures by involving senior leadership for approvals, ensuring buy-in.

- Use Clear Language and Visual Aids

- Make sure process documentation is in simple English. Also provide regional language translations if needed (e.g., Tamil, Hindi).

- Include flowcharts, diagrams, or videos to aid comprehension, especially for multilingual or less literate workforces.

- Detail Step-by-Step Procedures

- Break tasks into numbered steps, emphasizing safety in sectors like manufacturing.

- Balance SOP format standardization with flexibility for innovation where needed.

- Assign Roles with Accountability

- Define responsibilities explicitly, clearly defining the escalation paths

- Align with the company’s hierarchical culture, specifying authority levels.

- Incorporate Legal and Regional Requirements

- Highlight industry-specific regulations – RBI guidelines for banking, EPA for environmental compliance.

- Address state-specific variations

- Plan Training and Implementation

- Use hands-on workshops and digital tools (e.g., mobile-friendly platforms) for training.

- Leverage tech adoption via e-signatures and cloud-based SOP access.

- Establish Review and Update Mechanisms

- Schedule quarterly/annual reviews to adapt to regulatory changes (e.g., GST updates).

- Create feedback loops with employees to refine processes.

- Pilot Testing and Feedback

- Test SOPs in specific regions/teams to identify regional challenges.

- Use feedback to adjust for local practice like festival-related workflow changes.

- Formalize Approval and Documentation

- Obtain sign-offs from authorized personnel (e.g., HR Head, Plant Manager).

- Maintain audit-ready records, specifying formats (e.g., digital logs for tax compliance).

Why Choose PKC Management Consulting for SOP Development and Implementation?

An effective SOP requires following proper standard operating procedures setup guidelines. Here are some of the reasons why experts at PKC can be your top choice:

Expertise and Comprehensive SOP Services

We have a team of highly skilled consultants with extensive experience in framing and executing a standard operating procedure.

We offer a full range of services, from initial consultation and analysis to SOP development, implementation, and training.

Ensuring Consistency and Standardization in Business Processes

Successful implementation of SOPs with the help of expert providers like PKC can help in standardizing your processes and procedures and help improve consistency.

This ensures that everyone in your organization is following the same best practices.

Enhancing Quality and Customer Satisfaction Through Effective SOPs

Our standard operating procedures setup consultant helps you improve the quality of your products and services by implementing the best SOPs.

With your team working in a consistent and efficient manner, better outcomes and happier customers are guaranteed.

Boosting Efficiency and Productivity with Customized SOPs

Our SOPs are highly customized as per your needs.

They can help streamline your operations, eliminate unnecessary steps, and reduce the time and resources required to complete tasks. This leads to increased efficiency and productivity.

Achieving Compliance and Reducing Business Risks

Implementing an effective standard operating procedure with the help of our consultants can help reduce the risk of errors, accidents, and other issues that can impact your business.

Our experts stay updated on the changes in regulations and standards followed in your industry making sure you are always compliant.

Challenges in Adopting Standard Operating Procedure (SOP) + Solutions

Below are the key challenges faced by organizations in India in adopting SOP, with examples and solutions:

- Resistance to Hierarchical and Cultural Norms

Junior staff often hesitate to challenge processes and sometimes improvisations overrules SOPs.

Example: Factory workers might skip safety checks to meet production targets quickly.

Solution: Involve employees at all levels in SOP design to foster ownership and reward compliance to shift cultural attitudes.

- Resource Constraints in SMEs and Rural Sectors

Small businesses and rural industries lack funds, infrastructure, or trained staff to adopt SOPs.

Example: A small agro-processing unit cannot afford digital tools for process documentation.

Solution: Start with low-cost paper-based SOPs and leverage government schemes

- High Employee Turnover and Training Gaps

Frequent staff changes in sectors like manufacturing and hospitality disrupt SOP training continuity.

Example: A quick-service restaurant faces delays as new hires relearn food safety SOPs.

Solution: Simplify SOPs with pictograms and QR codes for quick access. You can also use micro-learning modules using platforms like WhatsApp.

- Inconsistent Implementation Across Regions

National companies face disparities in SOP adherence due to regional practices or infrastructure gaps.

Example: A hospital chain in UP follows sterilization SOPs, but its MPr branch lacks autoclaves.

Solution: Customize SOPs to regional realities and centralize monitoring with periodic audits.

- Technology Adoption Barriers

Uneven tech penetration limits digital SOP adoption.

Example: A rural healthcare center cannot access cloud-based SOP for healthcare manuals.

Solution: Use offline apps for SOP storage. Train staff via community radio or IVR systems in local languages.

- Sector-Specific Challenges

- Manufacturing: Balancing productivity with safety SOPs under pressure.

Solution: Integrate IoT sensors to automate compliance checks (e.g., machine temperature monitoring).

- Healthcare: Overburdened staff skipping steps in SOP for healthcare (e.g., patient consent forms).

Solution: Automate documentation with AI tools (e.g., digital patient records).

- Retail: Franchisees ignoring inventory SOPs to cut costs.

Solution: Link SOP compliance to incentives.

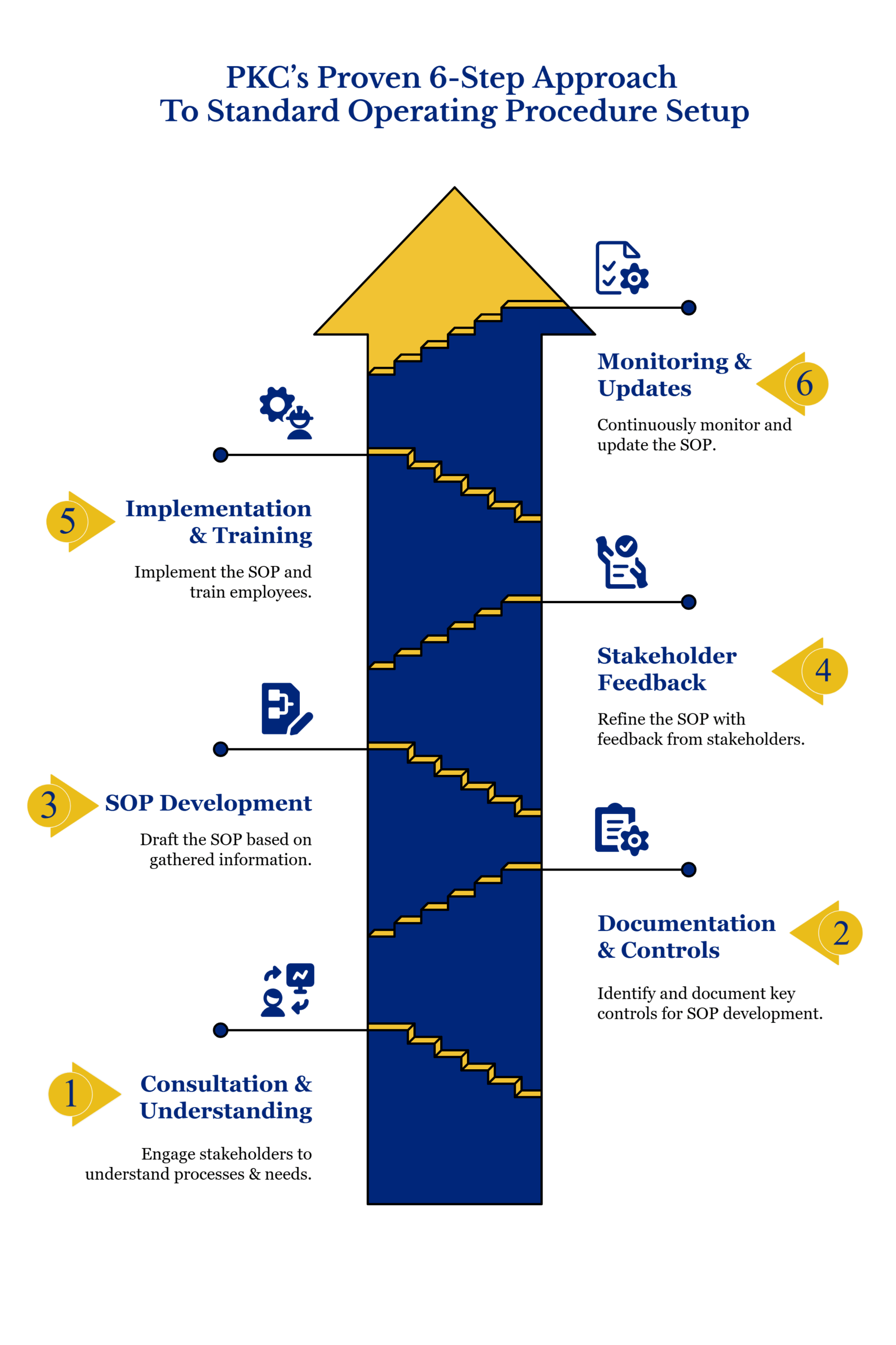

PKC’s Proven 6-Step Approach to Standard Operating Procedure Setup

Our standard operating procedures setup consultant follow a stepwise approach for the effective planning and execution of an SOP:

Step 1: Consultation & Process Understanding

We start by working with you closely to understand your business operations, workflow, and requirements.

This helps us identify the key steps involved and the critical points where the standard operating procedure should be implemented.

Step 2: Documentation & Key Controls Identification

Next, we create a detailed process map that outlines the inputs and outputs at each stage. This helps identify potential bottlenecks and areas for improvement.

At this stage, we also identify the key controls which include defining roles and responsibilities, setting performance metrics, and establishing quality standards.

Step 3: SOP Development & Drafting

Based on the process map and key controls, we develop a comprehensive standard operating procedure that outlines the steps involved in the process and the controls that need to be in place.

We ensure that the SOP is clear, concise and easy to understand and follow.

Step 4: Stakeholder Feedback & SOP Refinement

Once the PKC Management Consulting team shares the draft SOP, we will conduct discussions to gather feedback from the stakeholders.

We incorporate any suggestions or changes that you provide us into the final SOPs.

Step 5: SOP Implementation & Employee Training

Once the SOP is approved, we assist you in implementing it efficiently.

To integrate the standard operating procedure into all levels of the organization, we also provide the required training to employees.

Step 6: Ongoing Monitoring, Testing & SOP Updates

Our SOP setup consultant and team will monitor the SOP and conduct regular tests to ensure that it remains relevant and practical.

We also assist you in updating the SOP if needed.

Get Expert Help with Your SOPs from PKC Management Consulting

Frequently Asked Questions About SOPs and PKC Management Consulting

An SOPs is important because it helps ensure that the tasks or process is performed consistently and accurately. It provides clear instructions on how to complete the task, reducing the risk of errors and improving efficiency. It also helps ensure compliance with regulations and standards.

A standard operating procedure should include a detailed description of the task or process, the steps involved, the roles and responsibilities of each person involved, any necessary equipment or materials, and any relevant quality control or safety measures.

SOPs should be reviewed and updated regularly to ensure that they reflect any changes in the task or process being documented. At PKC we suggest doing it annually or whenever there are significant changes in the process.

Our SOP services can benefit businesses of all sizes including startups and large corporations. No matter how big or small your process is, our experts can help you develop and implement the best standard operating procedure that will work in your favour.

Our consultant provides expertise and guidance in developing effective SOPs. They bring a fresh perspective and provide best practices from their experience working with other organizations.

Expert verified

Expert verified