Being aware of the types of factory audits in India is extremely important if you’re running a business, sourcing products, or exporting goods.

Explore with us the most common types of factory audits in India which help you check if a factory is safe, clean, ethical, and producing quality stuff.

What Are Factory Audits & Why Are They Important?

Factory audits are formal inspections conducted to assess a manufacturing facility’s quality management systems, working conditions, safety standards, and compliance with local and international regulations.

Here’s why they are important:

- Avoid Legal Penalties: Prevents fines, shutdowns, or prosecutions for non-compliance with statutory laws.

- Ensure Product Quality: Reduces defects/recalls by enforcing standardized manufacturing processes.

- Protect Worker Safety: Minimizes accidents through rigorous hazard identification and corrective actions.

- Maintain Market Access: Meets mandatory certification (e.g., BIS, FSSAI) required to sell products domestically or globally.

- Build Buyer Trust: Ethical audits (e.g., SEDEX) secure contracts with big brands.

- Optimize Costs: Energy/process audits cut waste, lowering operational expenses by 15–30%.

- Mitigate Reputational Risks: Proves commitment to sustainability and ethics, shielding against activist or consumer backlash.

- Enable Continuous Improvement: Identifies operational gaps (e.g., lean manufacturing) to boost efficiency.

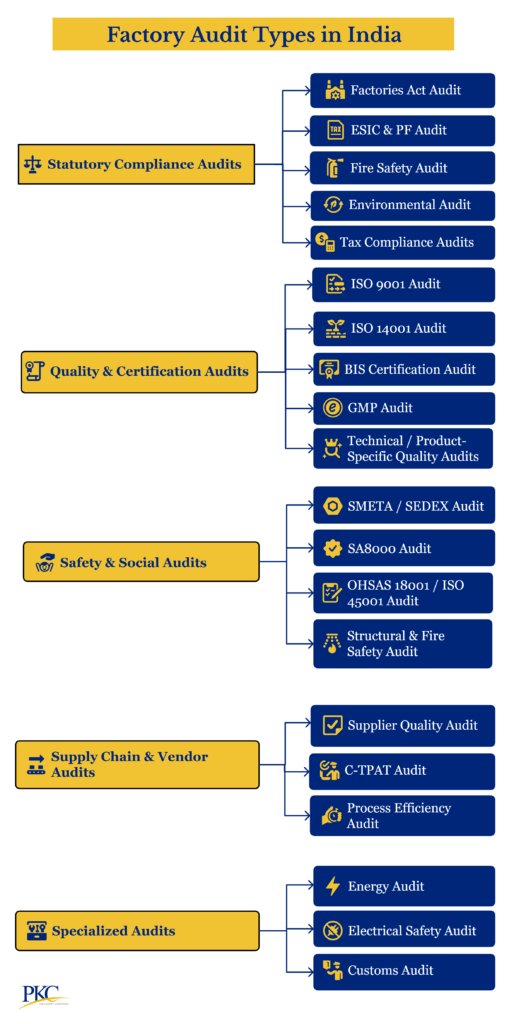

Different Kinds of Factory Audits for Indian Businesses

Here are some of the main types of factory audits in India with examples and recommended audit frequency:

1. Statutory Compliance Audits

These audits ensure that factories follow Indian labor, safety, tax, and environmental laws.

🏭 Factories Act Audit:

Verifies compliance with working hours, employee safety, and welfare facilities under the Factories Act, 1948.

Focus Areas:

- Working hours and shift rotations

- Safety equipment and training

- Restrooms, drinking water, canteens

- Recordkeeping and employee registers

Suggested For: All manufacturing units, especially medium and large factories

Recommended Frequency: Once a year

🏥ESIC & PF Audit

Ensures that employee insurance and provident fund contributions are correctly deducted and deposited.

Focus Areas:

- Employee registration under ESIC/PF

- Timely deposit of employer and employee contributions

- Accurate payroll calculations

- UAN linking and compliance with EPFO

Suggested For: Factories with more than 10 employees; garment, auto, pharma industries

Recommended Frequency: Quarterly or annually

🔥Fire Safety Audit

Checks the readiness of a factory to prevent and respond to fire emergencies.

Focus Areas:

- Fire alarms, extinguishers, and sprinklers

- Evacuation plans and signage

- Fire drills and emergency exits

- Electrical wiring inspections

Suggested For: All factories; especially textile, chemical, and electronics units

Recommended Frequency: Once every year (mandatory in most states)

🌱 Environmental Audit

Ensures that the factory meets environmental norms by Central/State Pollution Control Boards.

Focus Areas:

- Wastewater treatment

- Air and noise pollution control

- Hazardous waste disposal

- Emission levels and permits

Suggested For: Chemical, dyeing, tanneries, paper, and food processing factories

Recommended Frequency: Annually or as per consent renewal timeline

💰 Tax Compliance Audits (GST & Income Tax)

Confirms that the factory is paying correct taxes and filing returns as per law.

Focus Areas:

- GST return filing and ITC claim accuracy

- TDS compliance

- Annual income tax returns

- Invoicing and e-way bills

Suggested For: All registered businesses under GST or Income Tax Act

Recommended Frequency: Quarterly (GST) and annually (IT)

2. Quality & Certification Audits

These audits evaluate product and process quality to meet local and global standards.

📋ISO 9001 Audit

Evaluates the quality management system of a factory.

Focus Areas:

- SOPs for production and inspection

- Internal audits and corrective action

- Customer feedback systems

- Training records

Suggested For: All export-oriented units, electronics, automotive, machinery factories

Recommended Frequency: Every 3 years (with yearly surveillance audits)

🌍 ISO 14001 Audit

Checks if the factory has an environmental management system to control pollution.

Focus Areas:

- Risk analysis and waste control

- Resource optimization

- Environmental policy and goals

- Compliance tracking

Suggested For: Factories in environmentally sensitive sectors—dyes, paper, plastic, food

Recommended Frequency: Every 3 years (with yearly surveillance audits)

🏷️ BIS Certification Audit

Ensures the product meets Indian quality standards and is eligible for the ISI mark.

Focus Areas:

- Product specifications

- Quality testing reports

- Manufacturing practices

- Marking and labeling

Suggested For: Electronics, construction materials, consumer goods manufacturers

Recommended Frequency: Annually or based on product renewal

🧴GMP Audit (Good Manufacturing Practices)

Ensures hygienic production practices for consumer health and safety.

Focus Areas:

- Clean rooms and hygiene

- Raw material traceability

- Batch production records

- Contamination prevention

Suggested For: Pharma, food processing, cosmetics, and personal care factories

Recommended Frequency: Annually, especially for pharma/food

🔍Technical / Product-Specific Quality Audits

Evaluates compliance with specific product-related standards (e.g., automotive, aerospace, food).

Focus Areas:

- Product testing and certification

- Production line validation

- Material traceability

- Process consistency

Suggested For: Auto parts, aerospace components, medical device factories

Recommended Frequency: Before new product launches or exports

3. Safety & Social Audits

These ensure that employee rights, health, and safety are protected at the workplace.

🌐SMETA / SEDEX Audit

Assesses ethical sourcing and social compliance, based on ETI Base Code.

Focus Areas:

- Worker treatment

- Health and safety

- Ethical business practices

- Freedom of association

Suggested For: Textile, garment, and consumer product exporters to the UK and EU

Recommended Frequency: Once a year (mandatory for many EU/UK buyers)

🤝SA8000 Audit

Verifies compliance with international labor standards like no child labor, fair wages, and working hours.

Focus Areas:

- No forced or child labor

- Equal opportunity

- Disciplinary practices

- Legal wages and work hours

Suggested For: Garment factories, handicraft units, and export manufacturers

Recommended Frequency: Annually with periodic internal reviews

⚠️OHSAS 18001 / ISO 45001 Audit

Evaluates occupational health and safety management systems.

Focus Areas:

- PPE (Personal Protective Equipment) usage

- Safety training and hazard reporting

- Workplace accident records

- Risk management practices

Suggested For: Construction, chemicals, heavy manufacturing units

Recommended Frequency: Every 3 years (with annual checks)

🏢Structural & Fire Safety Audit

Assesses the physical safety of the building and fire readiness.

Focus Areas:

- Building load-bearing checks

- Exit route planning

- Fire drills and response teams

- Structural damage or cracks

Suggested For: Textile, food processing, and multi-story factory buildings

Recommended Frequency: Annually or whenever a major change occurs in building structure

4. Supply Chain & Vendor Audits

Audits conducted to evaluate vendors and suppliers for maintaining supply chain reliability.

🧪Supplier Quality Audit

Reviews supplier capabilities, raw materials, and delivery performance.

Focus Areas:

- Supplier capacity

- Incoming material checks

- Vendor reliability and compliance

- Quality consistency

Suggested For: OEMs in electronics, automotive, and FMCG sectors

Recommended Frequency: At the start of supplier relationship, then yearly

🚢C-TPAT Audit

Ensures compliance with supply chain security protocols for US-bound shipments.

Focus Areas:

- Container security

- Access control

- Employee screening

- Facility surveillance

Suggested For: Factories exporting to the United States

Recommended Frequency: Annually for exporters to the US

⚙️Process Efficiency Audit (Lean / Six Sigma)

Assesses how efficiently resources and time are used in production.

Focus Areas:

- Production line flow

- Waste reduction (time, material)

- Bottlenecks in process

- Value stream mapping

Suggested For: Automotive, electronics, and high-volume manufacturing units

Recommended Frequency: Every 6 to 12 months to track performance

5. Specialized Audits

Audits focused on high-risk or regulated operational areas.

💡Energy Audit

Measures energy consumption and recommends savings; mandatory for large units under BEE (Bureau of Energy Efficiency).

Focus Areas:

- Electrical consumption patterns

- Machine energy efficiency

- Power factor correction

- Renewable energy usage

Suggested For: Steel, cement, paper, chemical, and textile factories (Designated Consumers under BEE)

Recommended Frequency: Once every 3 to 5 years (mandatory for large power consumers under BEE)

⚡Electrical Safety Audit

Checks wiring, equipment, and electrical safety as per ISI norms.

Focus Areas:

- Circuit breakers and panels

- Earthing and grounding

- Load capacity checks

- Maintenance logs

Suggested For: Factories using heavy electrical equipment or operating in wet environments

Recommended Frequency: Annually

🛃Customs Audit (EOU / SEZ Units)

Audits export-oriented units for compliance with duty-free import regulations, re-exports, and customs requirements.

Focus Areas:

- Input-output norms

- Customs documentation

- Duty credit utilization

- Bond management

Suggested For: Export houses, SEZ units, and Export Oriented Units (EOUs)

Recommended Frequency: Based on customs department or SEZ authority schedule; usually once a year

Industry-Specific Factory Audits In India

Each industry has its unique risks, compliance requirements, and quality expectations. Here’s a quick look at the top audits recommended for each:

| Industry / Factory Type | Recommended Factory Audits |

| Textile & Garment Factories | SMETA / SEDEX Audit SA8000 Social Compliance Audit Fire & Structural Safety Audit Environmental Compliance Audit (Dyeing/Washing Units) |

| Food & Beverage Factories | FSSAI Compliance Audit GMP (Good Manufacturing Practices) Audit ISO 22000 (Food Safety Management) Audit Pest Control & Hygiene Inspection |

| Pharmaceutical Factories | GMP Audit (as per WHO or CDSCO) USFDA / EU-GMP Audit (for exporters) Environmental Audit (waste & water management) Cleanroom Validation Audit |

| Automotive Component Factories | IATF 16949 Quality Management Audit ISO 9001 Audit Supplier Quality Audit Lean Manufacturing / 5S Audit |

| Electronics Manufacturing Units | BIS Certification Audit (ISI Mark) ISO 9001 Quality Management Audit RoHS/CE Compliance Audit Electrical Safety Audit |

| Chemical & Paint Factories | CPCB / SPCB Environmental Audit ISO 14001 Environmental Management Audit Hazardous Waste Handling Audit Fire Safety & Explosion Risk Audit |

| Construction Material Factories | BIS Audit (Cement, Steel, Bricks) Emissions & Dust Control Audit ISO 9001 Quality Audit Equipment Calibration Audit |

| Export Oriented Units (EOUs) | Customs Audit (Bonded Warehouse Compliance) C-TPAT Supply Chain Security Audit SA8000 Labor Compliance Audit GST & Import Duty Audit |

How Can PKC Help With Factory Audits?

✅Trusted by 1,500+ clients for operational excellence

✅Multi-industry experience across manufacturing, retail, healthcare, finance sectors

✅Custom process audit checklists for manufacturing facilities

✅Identify and fix TDS, GST, EPF/ESI compliance issues

✅Technology-integrated audit solutions for accurate results

✅Regular communication and transparent progress updates throughout

✅Detect quality standards, process control, documentation gaps

✅Comprehensive risk mitigation and non-compliance identification services

✅Clear explanations of audit findings and recommendations

Frequently Asked Questions

- What is a factory audit?

A factory audit is a systematic inspection of a manufacturing facility to evaluate quality control systems, compliance, capacity, and working conditions.

- What are the main types of factory audits in India?

The main types include Quality Audit, Social Compliance Audit, Environmental Audit, C-TPAT Audit, Technical/Process Audit, and Security Audit.

- Are factory audits mandatory in India?

Some audits like environmental and labor compliance audits are legally mandated, while others are voluntary or requested by international buyers.

- Who conducts factory audits in India?

Audits can be performed by in-house teams, third-party audit firms like PKC Management Consulting, or government-approved agencies, depending on the audit type and purpose.

- How often should factory audits be conducted?

Audit frequency depends on the buyer’s policy, the type of audit, and past performance, but many conduct audits annually or semi-annually.

Expert verified

Expert verified