Quality control SOP in manufacturing in India is needed for consistent and compliant production.

This guide explains everything manufacturers in India need to know about QC SOPs from regulatory standards to industry-specific considerations, implementation process and more.

What is Quality Control SOP in Manufacturing?

A quality control Standard Operating Procedure (QC SOP) in manufacturing is one of the essential SOPs that manufacturers need for carrying out quality-related tasks during production.

The goal of QC SOP is to ensure that all processes are performed consistently, efficiently, and in compliance with internal standards and regulatory requirements.

Regulatory Bodies and Standards in India

In India, manufacturers are governed by multiple regulatory bodies and quality standards, depending on the industry and product type.

Let’s take a look at the key standards and regulatory bodies:

Bureau of Indian Standards (BIS)

National standards body responsible for product quality benchmarks.

Functions:

- Issues the ISI mark.

- Publishes over 20,000 standards across sectors.

- Mandatory for electrical goods, steel, cement, automotive parts, etc.

Food Safety and Standards Authority of India (FSSAI)

Regulates food safety and hygiene.

Scope:

- Enforces the Food Safety and Standards Act, 2006.

- Mandates hygiene SOPs, traceability systems, and food safety audits.

Central Drugs Standard Control Organization (CDSCO)

Regulatory body for drugs, cosmetics, and medical devices.

Functions:

- Oversees GMP compliance (Schedule M).

- Authorizes new drugs and medical devices.

- Monitors clinical trials and pharmacovigilance.

Automotive Research Association of India (ARAI) & ICAT

Certify vehicles and components for safety and emissions based on Automotive Industry Standards (AIS).

Other Supporting Bodies

- MoEFCC (Ministry of Environment, Forest and Climate Change): Environmental compliance.

- DGFASLI: Worker safety under Factories Act.

- NABL: Accreditation of testing/calibration labs.

Commonly Adopted Standards:

| Standard | Area of Focus |

| ISO 9001 | Quality Management Systems |

| ISO 22000 / FSSC 22000 | Food Safety Management Systems |

| ISO 13485 | Quality Systems for Medical Devices |

| ISO 14001 | Environmental Management |

| ISO 45001 | Occupational Health & Safety |

| WHO-GMP / Schedule M | Pharma Good Manufacturing Practices |

| IATF 16949 | Automotive Quality Management |

| CE Marking / RoHS / REACH | Export, electronics, and environmental standards |

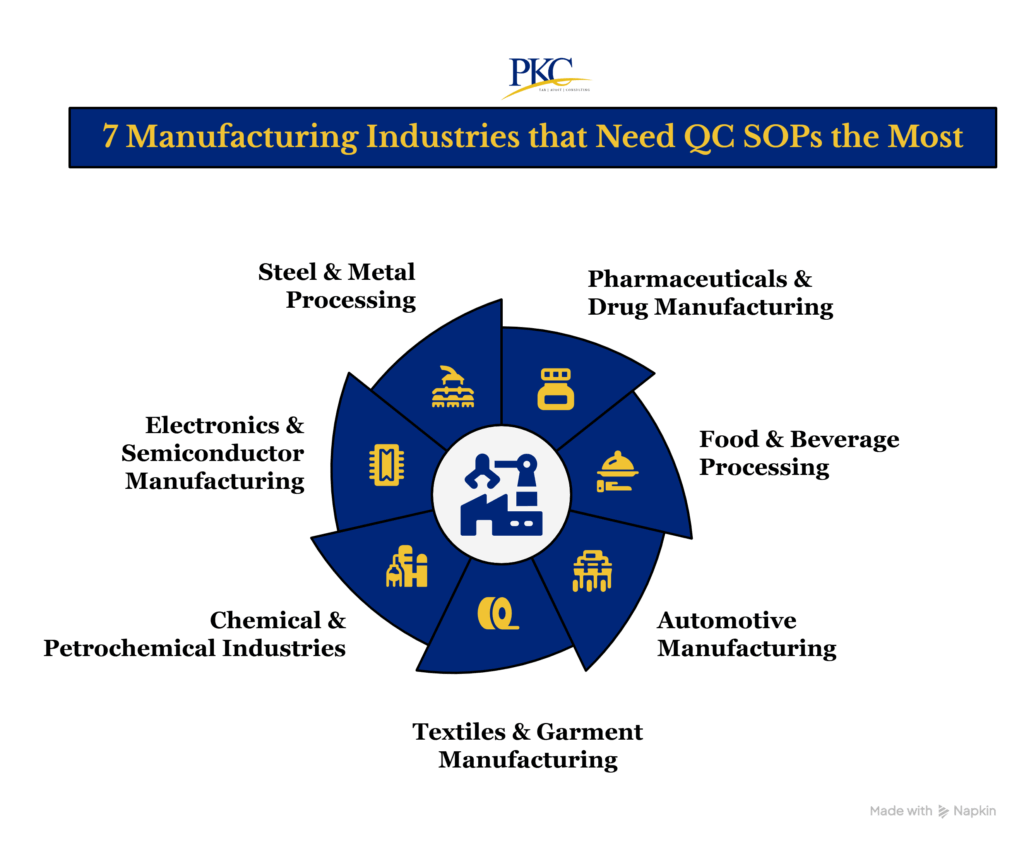

Manufacturing Businesses That Need Quality Control SOPs

Mostly all kinds of manufacturing industries benefit from implementing QC SOPs.

However, some sectors that are more tightly regulated due to safety, health, or legal risks must use QC SOPs

High-Risk, Highly Regulated Industries

1. Pharmaceuticals & Biotechnology: Governed by CDSCO, WHO-GMP, and ISO. SOPs required for every step: raw material testing, formulation, packaging, and stability testing.

Examples:

- A QC SOP prevented batch recall by detecting contamination early.

- An SOP for potency testing identified a deviation in a batch, ensuring safety

2. Medical Devices: Must comply with SOPs for sterilization, calibration, labeling, and risk analysis. Products like syringes, implants, and diagnostic equipment undergo rigorous quality control.

Examples:

- An SOP for sterility testing ensured surgical instruments were free from contamination.

- An SOP caught flaws in a hip implant’s coating before distribution.

3. Food & Beverage: Regulated by FSSAI and ISO 22000. QC SOPs cover hygiene, allergen control, temperature checks, and product traceability.

Examples:

- QC SOP avoided FSSAI penalty by ensuring allergen segregation

- SOP for pH testing ensured juice quality and consistency in every batch.

4. Automotive and Aerospace: SOPs for torque tightening, NDT, vibration testing, and final inspections. Compliance with IATF 16949 and ARAI/ICAT is crucial.

Examples:

- SOP on torque tightening reduced warranty claims by 15%.

- A QC SOP identified faulty welds in car safety systems, preventing potential failure

5. Chemicals and Paints: Includes SOPs for hazardous material handling, batch consistency, and waste disposal.

Examples:

- SOP for raw material testing prevented defective paint batches from being produced.

- SOP for viscosity checks ensured every paint batch met color and application standards.

Medium-Risk and Consumer-Facing Industries

6. Electronics and Electrical Goods: SOPs for safety testing, insulation resistance, drop tests, and labeling. Products often require BIS certification and RoHS compliance.

Example: An SOP for thermal testing identified overheating issues in power supplies early.

7. Textiles and Garments: SOPs for colorfastness testing, stitching checks, packaging, and export labeling.

Example: A QC SOP for fabric inspection ensured color and strength consistency.

Other Industries That Benefit from QC SOPs

- Furniture Manufacturing: Load testing, wood moisture control, finish quality.

- Plastic & Rubber Products: SOPs for injection molding parameters, tensile strength.

- Construction Materials: SOPs for cement composition, curing, and performance testing.

Quality Control SOP Manufacturing Template

QC SOPs when well created and implemented act like a compliance instrument, a training tool, and a foundation for quality assurance directly impacting safety, export readiness, and brand credibility.

Here a look at the template and sections each quality control SOP must have in manufacturing:

| Section | Description |

| Title and Identification Information |

|

| Purpose and Scope |

|

| Roles and Responsibilities |

|

| Reference Documents and Regulatory Compliance |

Cites legal and internal documents:

|

| Required Materials, Equipment & Tools |

Includes:

|

| Step-by-Step Procedures |

Covers:

|

| Quality Standards, Acceptance & Rejection Criteria |

|

| Deviation Handling & CAPA |

Protocol:

|

| Documentation & Record Keeping |

|

| Review, Approval & Change Control |

|

| Annexures, Flowcharts & Visual Aids |

Aids for clarity:

|

Core Elements of Quality Control SOPs in Indian Manufacturing

Let’s take a look at the different aspects that a QC SOP considers as part of essential quality checkpoints:

1. Incoming Material Inspection (IMI)

- Vendor Qualification & Documentation: Suppliers must be evaluated for technical capabilities, regulatory compliance (e.g., BIS), and risk exposure. Maintain an Approved Vendor List (AVL), signed quality agreements, and certificates like COAs and calibration reports.

- Material Inspection Procedures Verify deliveries against purchase orders. Inspect packaging, labeling, and sample materials. Testing includes physical, chemical, and microbiological methods. Conformity must be documented using GRNs and traceability records.

- Acceptance Criteria: Define specification limits based on product standards or regulatory norms. Use AQL-based sampling plans for consistency.

2. In-Process Quality Control (IPQC)

- Critical Control Points (CCPs):: Identify process stages (e.g., mixing, heating, filling) where quality is most vulnerable. Monitor parameters like temperature, time, pressure, and viscosity.

- Real-Time Monitoring: Install sensors, alarm systems, and digital dashboards to detect deviations instantly. Adapt to Indian conditions like power outages and workforce variability.

- Checkpoints: Perform inspections at defined intervals. Use SPC tools (e.g., control charts) to track stability and prevent defects.

3. Finished Product Testing

- Testing Protocols: Conduct physical, functional, and chemical tests on finished goods. Use sampling plans based on lot size and risk. For sensitive industries (e.g., pharma, food), microbiological testing and shelf-life evaluations are essential.

- Final Batch Release: Ensure all specifications are met. Approvals should follow a defined hierarchy and include CoA generation with test results, batch info, and sign-off by authorized personnel.

- Packaging Verification: Check for sealing, labeling, and shelf-life compliance to prevent market complaints or regulatory issues.

4. Equipment Calibration & Maintenance

- Calibration Schedules: Maintain routine calibration and verification logs for all instruments (e.g., balances, moisture analyzers). Use equipment ID tracking and record last calibration dates.

- Preventive Maintenance: Schedule routine checks to avoid unexpected failures. Document maintenance activities, and ensure backup plans exist for critical equipment.

5. Non-Conformance Handling & CAPA

- Defect Identification: Clearly label and segregate non-conforming products. Use visual indicators and electronic tracking to prevent mix-ups.

- Evaluation & Disposition: Perform root cause analysis (5-Why, Fishbone) and decide on rework, scrap, or return. Implement corrective and preventive actions (CAPA) and verify their effectiveness through follow-ups.

- Customer Complaints: Respond promptly, investigate, and share findings. For critical defects, notify regulatory bodies as required.

Industry-Specific QC SOP Considerations for Manufactures in India

While the core SOP structure like title, scope, procedure, roles, documentation, etc. is universal, the content focus must be industry-specific.

Here are some industry specific considerations for Manufacturing QC SOP in India:

Pharmaceuticals & Medical Devices

QC SOPs must ensure product safety, efficacy, and regulatory conformity across the product lifecycle.

Regulatory Authorities:

- CDSCO (India)

- Schedule M of the Drugs & Cosmetics Act

- WHO GMP, US FDA, EU EMA (for export)

QC SOP Focus Areas:

- Raw Material Testing: Identity, assay, and impurity profiling using validated analytical methods.

- In-Process Checks (IPQC): Weight variation, tablet hardness, disintegration, pH, and viscosity during manufacturing.

- Environmental Monitoring: Airborne particles, surface swabs, and personnel hygiene in cleanrooms.

- Sterility Assurance: For injectables and medical devices, sterility tests and bioburden checks are mandatory.

- Finished Product Testing: Stability, dissolution, microbial limits, and packaging integrity.

- Change Control and Deviation Handling: Include CAPA protocols, root cause analysis, and regulatory reporting (if required).

Documentation QC:

- Batch Manufacturing Record (BMR)

- Certificate of Analysis (CoA)

- Instrument calibration logs

- Cleaning validation records

Food and Beverage Industry

Prevent biological, chemical, and physical hazards and ensure food safety for consumption.

Regulatory Authorities:

- FSSAI (Food Safety and Standards Authority of India)

- ISO 22000, HACCP

- Legal Metrology for labeling compliance

QC SOP Focus Areas:

- HACCP Implementation: SOPs must support critical control points (e.g., pasteurization temperature, cooking time).

- Personal Hygiene & Sanitation SOPs: Hand washing, clothing, equipment sanitization.

- Allergen Control: Dedicated tools and surfaces for allergen-containing ingredients.

- Raw Material Checks: Pesticide residues in produce, freshness of milk/meat, supplier verification.

- Temperature Control: Cold chain integrity in warehousing, transport, and retail supply.

Documentation:

- Sanitation logs

- Temperature and humidity monitoring sheets

- Raw material inspection reports

- Pest control and waste management logs

Automotive Manufacturing

Guarantee vehicle safety, part durability, and global compliance.

Regulatory Authorities:

- ARAI, MoRTH (India)

- ISO/TS 16949 / IATF 16949

- AIS (Automotive Industry Standards)

QC SOP Focus Areas:

- Dimensional Accuracy & Tolerance Checks: For CMM (Coordinate Measuring Machine) usage, Go/No-Go gauges.

- Functional Testing: EOL (End-of-Line) SOPs for brake, lighting, suspension, engine, and electronics.

- SPC (Statistical Process Control): SOPs on how to chart and act upon process trends.

- Supplier Audits & PPAP: Part Production Approval Process SOPs to standardize parts from Tier-1/2 vendors.

- Assembly Line Control Plans: Error-proofing (Poka-yoke), torque checks, RFID/barcoding SOPs.

Documentation QC:

- Quality inspection reports

- Tool and jig calibration records

- Control plans and FMEA (Failure Modes and Effects Analysis)

- Customer complaints and CAPA logs

Textiles and Garments

Deliver aesthetic, safe, and export-compliant garments/fabrics.

Regulatory Authorities:

- BIS (for domestic quality compliance)

- Oeko-Tex / GOTS / SEDEX (for exports)

- Buyer-specific quality codes

QC SOP Focus Areas:

- Fabric Inspection: Use of 4-point system, documentation of knots, stains, weft issues.

- Colourfastness Testing: Against washing, rubbing, perspiration, and light.

- Needle Detection: All garments, especially children’s wear, to avoid metallic contamination.

- AQL Sampling: Sampling procedures based on Acceptable Quality Limit, typically 1.5–2.5 for premium buyers.

- Workplace Safety: Emergency evacuation, chemical handling (in dyeing), and needle break protocols.

Documentation:

- Defect summary sheets

- Needle detector logs

- Wash care and shrinkage test records

- Export packing lists and buyer inspection reports

Electronics and Electricals

Ensure electrical safety, functionality, and durability under real-world conditions.

Regulatory Authorities:

- BIS (Compulsory Registration Scheme)

- RoHS / WEEE (for EU exports)

- IEC standards (for product categories like batteries, lamps, etc.)

QC SOP Focus Areas:

- Product Testing: Voltage withstand, short-circuit, thermal resistance, dielectric strength.

- Assembly: ESD (Electrostatic Discharge) prevention in sensitive electronic zones.

- Environmental Testing: For high/low temperature cycling, humidity, drop, vibration.

- Labeling and Certification: For BIS mark, CE marking, energy labeling.

- Battery & PCB Testing: For insulation resistance, solder joint quality, performance life.

Documentation:

- Electrical test reports

- Calibration certificates

- BOM (Bill of Materials) traceability

- Component lot traceability

How to Implement Quality Control SOP for Manufacturing in India

QC SOP can make a real impact only when it’s understood, adopted, and followed on the factory floor.

Here’s an efficient step-by-step implementation framework:

Phase 1: Foundational Setting

1. Define Clearly Objective and Regulatory Scope

- Need for QC SOP: Compliance, exports, or internal quality improvement

- Scope: Raw material testing, in-process checks, packaging inspection, etc.

Example: This SOP outlines procedures to ensure all incoming raw materials for chocolate bars meet FSSAI standards for microbiological and physical parameters.

2. Map Critical Quality Processes

- Identify all processes impacting quality, use flowcharts or process maps.

- Perform a Gap Analysis to identify:

- Missing controls

- Unclear responsibilities

- Compliance risks

Prioritize SOPs for:

- High-risk areas (e.g., sterility, allergen control, calibration)

- Regulatory-critical steps

- Frequently non-compliant processes

3. Form a Cross-Functional Implementation Team

Bring together:

- QA/QC leaders

- Production supervisors

- Maintenance and EHS officers

- Shop-floor operators

Assign responsibilities for:

- Drafting

- Training

- Monitoring

- Document control

Phase 2: SOP Writing & Development

4. Write Practical, Clear SOPs

- Simple (avoid legal or overly technical language)

- Visual (use photos, diagrams, flowcharts)

- Actionable (step-by-step, no ambiguity)

Include all the key components in the QC SOP as shared above.

5. Get Review and Approval

- Have SOPs reviewed by QC/QA and approved by senior management (Plant Head, Quality Head).

- Apply version control (Rev. 1, 2, etc.) to maintain audit traceability.

Phase 3: Training The People

6. Deliver Effective Training

- Conduct hands-on sessions

- Use local languages and visual aids

- Simulate real scenarios (e.g., mock quality inspections)

- Validate learning with quizzes, drills, or role-play.

7. Document All Training

Maintain training records with:

- Dates

- Trainer names

- Attendee lists

- Assessment scores

This is mandatory for audits by BIS, FSSAI, ISO, or pharma regulators.

Phase 4: Gradual Execution & Implementation

8. Roll Out in Phases

- Start with one critical SOP per department

- Monitor actual execution on the floor

- Gather feedback on:

- Feasibility

- Missing tools/resources

- Time taken vs. expectation

Pilot Example: Implementing a packaging QC SOP in one shift. Measure rejection rates before and after.

9. Enable Tools & Infrastructure

Ensure the SOP can be followed by providing:

- Calibrated equipment

- Logbooks or digital entry systems

- Visual reference samples (e.g., “OK vs. NOT OK” boards)

- Signage with critical control points

10. Keep Real-Time QC Records

- Use checklists, logbooks, or mobile apps to document:

- Inspections

- Deviations

- Maintenance/calibration

- Ensure entries are timestamped and signed

These are vital for:

- Internal QA

- Regulatory audits

- Root cause investigations

Phase 5: Review & Improvement

11. Conduct Regular Monitoring & Audits

- Supervisors should verify SOP compliance daily.

- Perform internal audits (quarterly/bi-annually).

- Use checklists for audit consistency.

Track metrics like:

- Defect rates

- Deviation reports

- Rework percentages

- Customer complaints

12. Implement CAPA System

When SOPs are not followed:

- Document the non-conformance

- Conduct root cause analysis

- Apply Corrective Action (e.g., re-training)

- Apply Preventive Action (e.g., SOP update)

Log and review CAPA closures in monthly quality review meetings.

13. Review and Update SOPs Periodically

Review SOPs annually or after:

- Regulatory changes (e.g., FSSAI limits)

- Process changes (new equipment, raw materials)

- Customer complaints or audit findings

Update SOP version and re-train staff if any major changes occur.

Free Sample Quality Control SOP for Manufacturing in India PDF

Here’s an example of a comprehensive Quality Control SOP for an automotive brake pad manufacturing which has stringent quality requirements.

Benefits of Quality Control SOP in Manufacturing India

1. Consistent Product Quality: SOPs ensure every task is performed the same way, every time, reducing variation and maintaining uniform quality across batches and shifts.

2. Regulatory Compliance: They help manufacturers meet Indian and global standards like BIS, FSSAI, CDSCO, GMP, and ISO, making audits smoother and avoiding penalties or recalls.

3. Faster & Easier Employee Training: With clear, written instructions, new workers can be trained quickly and accurately, especially useful in high-turnover industries like textiles and food.

4. Fewer Defects and Less Waste: Standardizing quality checks reduces human error, rework, and raw material wastage, improving both quality and cost-efficiency.

5. Improved Workplace Safety: SOPs outline safety procedures for handling machinery, chemicals, and equipment, helping prevent accidents on the factory floor.

6. Better Customer Satisfaction: Fewer defects mean fewer complaints. Consistent quality boosts trust, especially for exporters dealing with strict global buyers.

7. Support for Continuous Improvement: Well-documented procedures make it easier to spot inefficiencies and drive process improvements using tools like Lean or Six Sigma.

8. Stronger Brand and Market Access: Reliable SOP systems boost your brand image, help win contracts, and open doors to both domestic and export markets under “Make in India.”

How Can PKC Help Manufacturers in SOP Implementation?

✅ Tech-enabled SOP solutions with digital transformation integration

✅ Dedicated in-house manufacturing process improvement specialists

✅ Production efficiency optimization through structured SOP frameworks

✅ Quality control standardization preventing costly manufacturing errors

✅ Employee training programs ensuring consistent SOP adoption

✅ Cross-functional team approach for comprehensive manufacturing SOPs

✅ Industry-specific Manufacturing SOP templates for faster implementation cycles

✅ Continuous improvement methodologies built into SOP structures

✅ Affordable consulting rates with guaranteed high ROI

FAQs About QC SOP for Manufacturing

A Quality Control SOP is a step-by-step document that guides workers on how to maintain product quality. It ensures consistency, safety, and compliance across all manufacturing processes.

SOPs reduce errors, improve efficiency, and help meet Indian regulations like BIS, FSSAI, and CDSCO. They also build trust with global buyers who expect consistent quality.

Agencies like BIS, FSSAI, CDSCO, and international bodies like ISO oversee quality standards. They set the benchmarks that Indian manufacturers must follow.

Pharmaceuticals, food & beverages, automotive, textiles, and electronics depend heavily on QC SOPs. These industries face strict safety and export compliance requirements.

It can lead to poor product quality, safety risks, and regulatory penalties. In export markets, it may also cause shipment rejections.

Expert verified

Expert verified