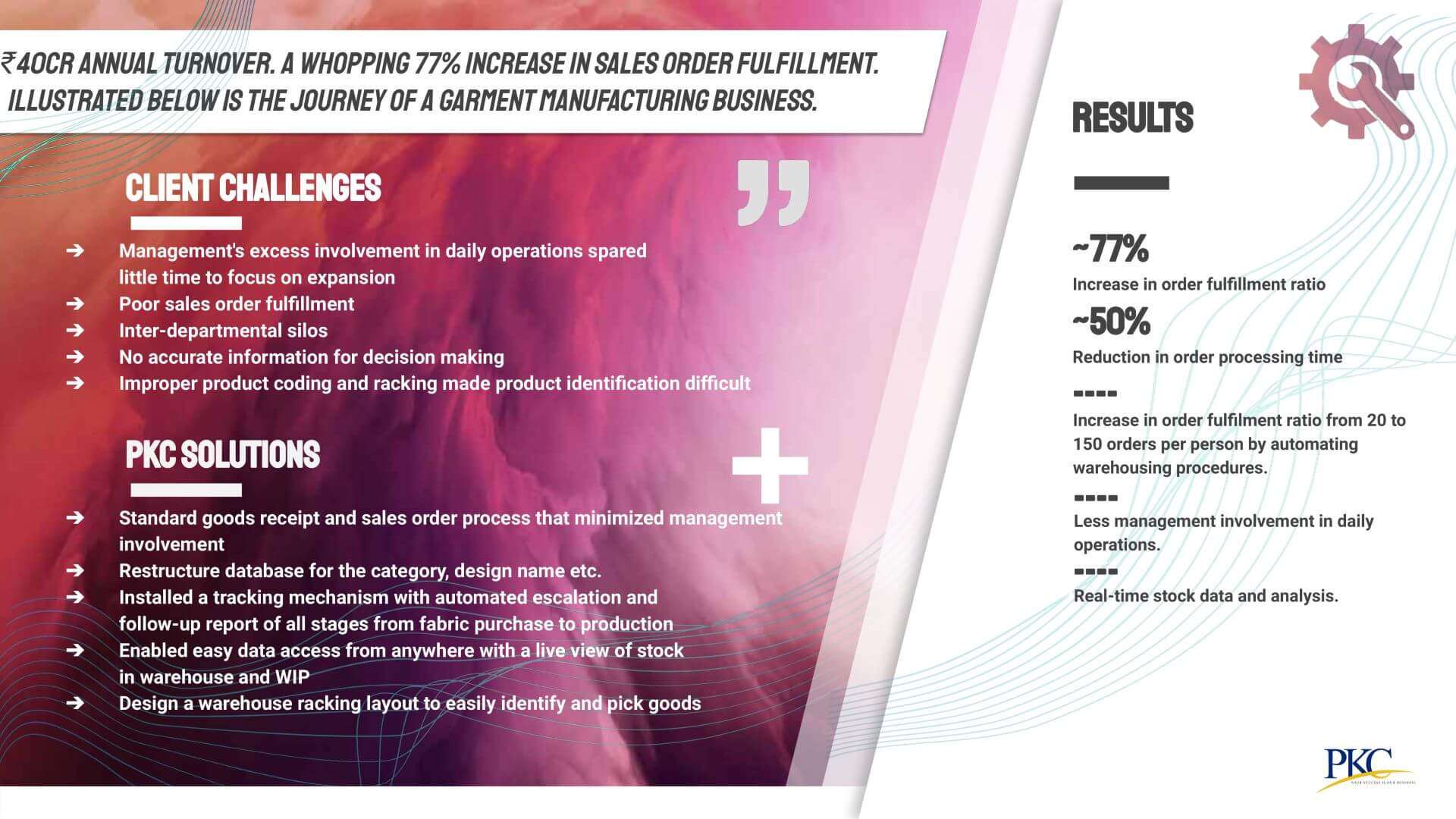

Client Challenges

- Management’s excess involvement in daily operations spared little time to focus on expansion

- Poor sales order fulfillment

- Inter-departmental silos

- No accurate information for decision making

- Improper product coding and racking made product identification difficult

PKC Solutions

- Standard goods receipt and sales order process that minimized management involvement

- Restructure database for the category, design name etc.,

- Installed a tracking mechanism with automated escalation and follow-up report of all stages from fabric purchase to production

- Enabled easy data access from anywhere with a live view of stock in warehouse and WIP

- Design a warehouse racking layout to easily identify and pick goods

Results

- ~77% increase in order fulfillment ratio

- ~50% reduction in order processing time

- Increase in order fulfillment ratio from 20 to 150 orders per person by automating warehousing procedures

- Less management involvement in daily operations

- Real-time stock data and analysis