Inventory turnover is how many times the company rotates its inventory

during the year.

For example, if a company’s sale is 100 crores and the average inventory

maintained is 20 crores, then the inventory turnover would be five times

(100 crores/20 crores)

Tracking inventory turnover and benchmarking it against internal targets

and external industry standards help to focus efforts and optimize

the inventory

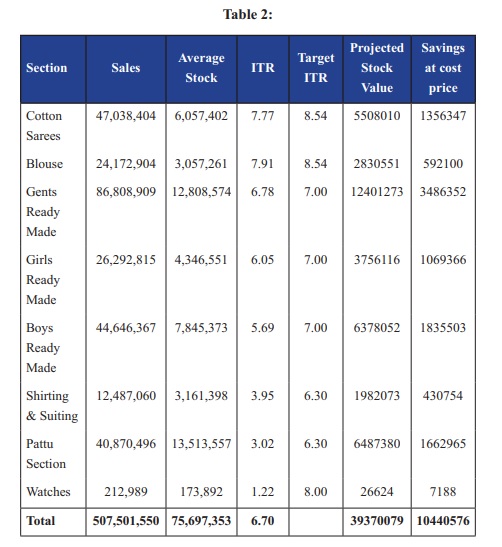

This is how a company does its inventory turnover analysis and

benchmarking:

Step 1 Split the product portfolio into logical sections. For instance, in

the textile business, product sections could be men’s formals,

men’s casuals, women’s western wear, lingerie, pattu, boy’s

readymade, etc.

Step 2 Get the average inventory and sales for each section for a

year and compute the inventory turnover using the formula

mentioned above.

Step 3 Now setup section-wise target benchmarks to achieve. For

example, ten times for lingerie, six times for pattu, etc. These

targets depend on the industry, and product nature and should

be achievable.

Once ITR is calculated, set up internal benchmarks (Target ITR) and

take action to improve the turnover.

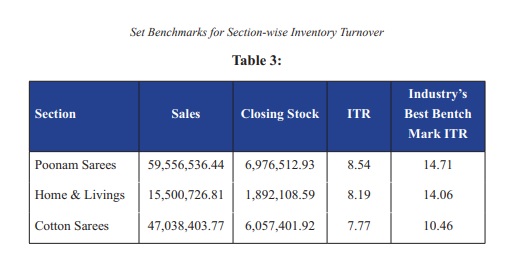

The benchmarks can also be set against industry standards to see how

the company is operating against the industry.

Pro Tip

Ways to improve the Inventory Turnover Ratio (ITR)

- Reduce Procurement Lead times

– Procure frequently & make arrangements with vendors and

transporters to reduce the lead time from PO to GRN. This

enables the company to keep adequate levels of inventory

in the warehouse and procure frequently. - Replenish as per Market demand

– Perform regular sales analysis to understand how products

are moving and keep stock which matches the demand and

lead time. - Setup maximum stock levels for each section