Selecting the best ERP for manufacturing industry is an important decision that can impact your workflows and overall performance.

Explore with us the top ERP systems for the manufacturing sector – be it small, medium or large. We also share the key factors you need to consider while choosing the best option.

What is Manufacturing ERP and How It Benefits the Industry?

A Manufacturing ERP system is a specialized software solution designed to streamline and automate core manufacturing processes.

It helps manufacturers manage everything – from buying raw materials to shipping out finished goods by connecting departments like production, inventory, sales, finance, and HR, all in one system.

Benefits of ERP for Manufacturing Industry

- Automates tasks (data entry, orders, scheduling), speeding production, cutting errors, and connecting departments.

- Instant insights into production, inventory, and supply chain, improving collaboration and accuracy.

- Tracks standards, alerts deviations, and reduces rework, improving customer satisfaction and lowering risks.

- Enables analysis, forecasting, optimized pricing, and efficient resource allocation for proactive management.

- Optimizes inventory and material availability, reducing costs and improving delivery.

- Allow manufacturers of all sizes to scale and adapt to market changes.

Top Features to Look for in the Best ERP for Manufacturing Industry

Manufacturing industry has unique operational complexities that require a specialized ERP system. Here are some must-have features to look for:

Production Planning & Scheduling

Helps meet tight deadlines, reduce idle time, and optimize resource allocation.

- Automated Work Order Management – Streamlines job scheduling and dispatch.

- Capacity Planning – Ensures optimal machine & labor utilization.

- Drag-and-Drop Scheduling – Visual tools for quick adjustments.

- Deadline Tracking – Avoids delays with real-time progress updates.

Quoting and Estimating

Ensures competitive pricing, faster order processing, and better profit margins.

- Automated Cost Calculation – Factors in material, labor, and overhead costs for precise estimates.

- Template-Based Quoting – Pre-built templates for faster proposal generation.

- Real-Time Pricing Updates – Adjusts quotes based on current material costs and supplier rates.

- Approval Workflows – Ensures quotes are reviewed before sending to clients.

- What-If Analysis – Simulates different scenarios (price changes, discounts) to optimize profitability

Shop Floor Management

Minimize downtime, improve productivity, and ensure on-time deliveries.

- Real-Time Production Tracking – Monitors work orders, machine status, and operator efficiency.

- Paperless Work Instructions – Digital SOPs and drawings accessible on shop floor tablets.

- Machine Integration (IoT) – Collects data from machines for predictive maintenance.

- Quality Checkpoints – Built-in inspections to reduce defects and rework.

- Labor & Machine Utilization Reports – Identifies bottlenecks and optimizes resources.

- Andon System Alerts – Instant notifications for issues (e.g., machine breakdowns).

Inventory & Warehouse Management

Reduces wastage, ensures JIT inventory, and improves warehouse efficiency.

- Multi-Location Stock Tracking – Manage inventory across factories & warehouses.

- Barcode/QR Code Scanning – Minimizes manual errors in stock handling.

- Batch/Expiry Tracking – Critical for pharma, FMCG, and food industries.

- Automated Replenishment Alerts – Prevents stock outs or overstocking.

Bill of Materials (BOM) Management

Ensures accurate material planning and cost control, crucial for automotive, electronics, and machinery sectors.

- Multi-Level BOM Support – Handles complex product structures.

- Revision Control – Tracks engineering changes in product designs.

- Material Cost Estimation – Auto-calculates production costs.

Costing & Budget Control

Helps manufacturers maintain competitive pricing and higher profit margins.

- Overhead Allocation – Distributes indirect costs accurately.

- Profitability Analysis – Compares product-wise revenue vs. costs.

Real-Time Reporting & Dashboards

Enables data-driven decisions for factory managers and business owners.

- Customizable Dashboards – Key metrics like OEE, downtime, and production yield.

- Drill-Down Analytics – Identifies bottlenecks in workflows.

- Automated Reports – Generates MIS, P&L, and inventory reports.

GST & Compliance Support

Ensures smooth tax filings and avoids penalties for non-compliance.

- Auto-GST Calculation – Supports GST, TDS, and e-invoicing.

- E-Way Bill Integration – Simplifies logistics compliance.

- Audit Trails – Maintains records for tax inspections.

CRM & Vendor Management

Strengthens supplier & customer relationships, crucial for Indian MSMEs.

- Supplier Performance Tracking – Rates vendors on delivery time & quality.

- Purchase Order Automation – Streamlines procurement.

- Customer Order History – Improves after-sales service.

Integration with Accounting & Banking

Reduces accounting errors and speeds up financial processes.

- Seamless Tally/QuickBooks Sync – Avoids manual data entry.

- Bank Reconciliation – Matches transactions automatically.

- Payment Gateway Links – Facilitates faster vendor/customer payments.

Cloud Access & Mobile Support

Supports hybrid work models and multi-location factories.

- Remote Monitoring – Access production data from anywhere.

- Mobile Alerts – Notifications for stock levels, machine breakdowns.

- Offline Mode – Works in low-connectivity areas.

Localization for Indian Market

Ensures smooth adoption across Indian shop floors.

- Multi-Language (Hindi, Tamil, etc.) – Improves workforce adoption.

- MSME-Friendly Pricing – Affordable for small manufacturers.

- Make in India Compliance – Supports domestic procurement policies.

Industry 4.0 & Smart Manufacturing

Prepares Indian factories for digital transformation and automation.

- IoT & Machine Monitoring – Predictive maintenance alerts.

- MES Integration – Bridges ERP with shop-floor machines.

- AI-Based Demand Forecasting – Optimizes production planning.

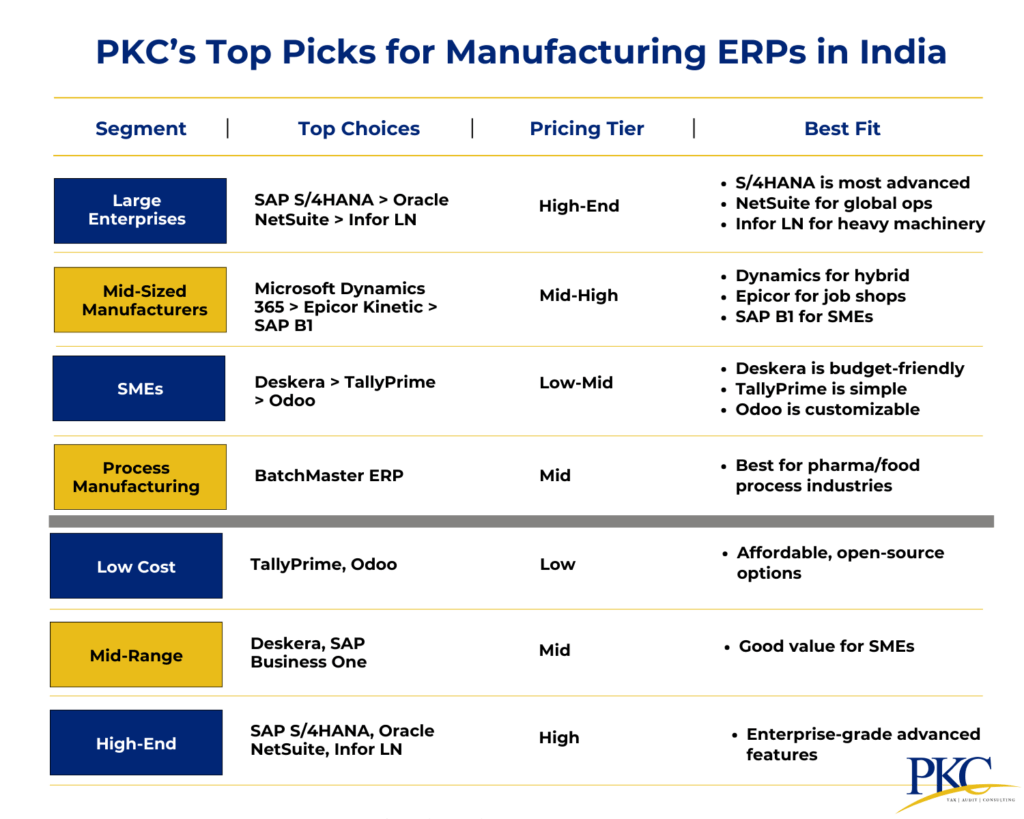

PKC’s Top Picks for Manufacturing ERPs in India

Top 10 Manufacturing ERP Systems in India

At PKC Management Consulting, we have over two decades of experience working with manufactures from different verticals.

Here are the top ERP systems we usually recommend for Indian businesses.

1. SAP S/4HANA

An advanced, integrated ERP suite designed for large enterprises, it offers end-to-end manufacturing process management.

KEY FEATURES:

- Real-time tracking of materials and finished goods

- AI-driven predictive maintenance & quality control

- Advanced production planning and MRP

- Full compliance with Indian GST and financial standards

- Global compliance (GST, IFRS, etc.)

PROS:

✅Cloud-based, reducing hardware needs and improving accessibility

✅Seamless integration with analytics tools and other applications

✅Fast data extraction and real-time insights

✅Scalable for large and growing organizations

CONS:

❌Expensive licensing & implementation

❌Requires skilled SAP consultants

❌Can be overwhelming for new users and smaller teams

❌Occasional connectivity and integration issues

2. SAP Business One

Provides a unified platform for all core operations. SAP B1 is widely adopted across India and is a great choice for small to mid-sized manufacturers needing enterprise-grade features.

KEY FEATURES:

- Simplified version of SAP, made for SMEs

- Integrated financial, sales, and supply chain management

- Localized for Indian businesses with GST support

- MRP, production planning, and real-time reporting

- Quality control throughout procurement and manufacturing

PROS:

✅Quick implementation and easy to use for SMEs

✅Real-time data access and customizable workflows

✅Automatic alerts for critical business events

✅More affordable than SAP S/4HANA

CONS:

❌Limited scalability for large enterprises.

❌Lacks advanced Industry 4.0 features

❌Limited flexibility in module selection

❌.May feel complex for very small businesses

3. Infor LN

A cloud-ready ERP solution focused on complex manufacturing environments, including discrete and project-based manufacturing like aerospace, automotive, and machinery.

KEY FEATURES:

- Built-in tools for engineer-to-order (ETO) and make-to-order (MTO)

- Cloud deployment and Indian compliance available

- Advanced supply chain and production management

- Real-time visibility into inventory and manufacturing

- Multi-site & multi-company support.

PROS:

✅Highly customizable for complex manufacturing needs

✅Strong project-based and discrete manufacturing features

✅Good for global supply chain management.

CONS:

❌Expensive for SMEs

❌ May require specialized training

4. Microsoft Dynamics

Integrates seamlessly with other Microsoft products and offers robust manufacturing capabilities.

KEY FEATURES:

- Seamless integration with Excel, Power BI, Teams

- Real-time production tracking

- Cloud-based with Indian localization

- Real-time analytics with Power BI integration

- Unified operations, finance, and manufacturing modules

- AI-powered demand forecasting & warehouse automation.

PROS:

✅Modular, scalable, and integrates well with Microsoft ecosystem

✅Cloud-based, flexible deployment

✅Strong for mixed-mode manufacturing.

CONS:

❌Customization can increase complexity and costs

❌Requires ongoing training for optimal use

❌ Microsoft ecosystem adoption preferred

5. Epicor Kinetic

Designed specifically for manufacturers, it offers a wide range of industry functionality and customization.

KEY FEATURES:

- Covers production, project management, quality, and compliance

- Intuitive dashboards and workflow automation

- Suited for discrete and mixed-mode manufacturing

- Scalable for Indian plants and factories

- Advanced MES & quality management

- Global compliance support

PROS:

✅Industry-specific features and deep customization

✅Both cloud and on-premise options

✅Good for lean manufacturing

CONS:

❌Implementation can be complex

❌May require specialized consultants

❌UI could be better

6. Oracle NetSuite

Cloud-based ERP offers multi-currency support. Most suited for growing manufacturers with multi-location operations.

KEY FEATURES:

- End-to-end supply chain & financial management

- Scales easily across branches or international plants

- Strong financial reporting and Indian tax compliance

- Integrated with supply chain and warehouse management

- Real-time analytics & demand planning

PROS:

✅Cloud-native with high scalability

✅Suited for multi-location businesses

✅Customizable dashboards and reporting

CONS:

❌Higher cost for advanced features

❌Customization may require expert support

❌Expensive for small businesses

7. Deskera ERP

Cloud-based platform, offering manufacturing, inventory, and accounting modules. It is popular among pharma, packaging, and light manufacturing

KEY FEATURES:

- All-in-one suite: CRM, HR, finance, and inventory

- Simple UI with GST-ready invoicing

- Mobile-friendly interface

- BOM management and production planning

- GST-compliant invoicing & reporting

PROS:

✅Affordable and easy to implement

✅Good for small-scale manufacturers

CONS:

❌Lacks advanced shop floor control

❌ Limited third-party integrations

❌May not scale well for very large enterprises

8. BatchMaster ERP

Specializes in process manufacturing, particularly for industries like food, chemicals, cosmetics, and pharma.

KEY FEATURES:

- Built-in batch processing and formula management

- Compatible with Indian tax rules and safety standards

- Formula & batch tracking with expiry management

- FDA & GMP & other important compliances

- Quality control & lab integration.

PROS:

✅Deep process manufacturing functionality

✅Integrates with popular accounting platforms

✅Strong regulatory compliance.

CONS:

❌Less suitable for discrete manufacturing

❌May require industry-specific expertise

❌Expensive for small players

9. TallyPrime

Developed in India, this is an affordable option with manufacturing extensions for basic production management.

KEY FEATURES:

- Easy-to-use interface

- Add-ons available for production tracking, job work, and BOM

- Integrated accounting and GST compliance

- Low cost, local support, and offline access

- Inventory and warehouse control

PROS:

✅Simple, familiar interface for Indian businesses

✅Affordable and quick to deploy

CONS:

❌Not scalable for large factories

❌ Limited automation & analytics

❌Not suitable for complex operations

10. Odoo

Last on our list of best ERPs for manufacturing in India is this open-source option with a modular structure, allowing manufacturers to tailor the system to their needs.

KEY FEATURES:

- Modular apps for manufacturing, inventory, HR, CRM, and more

- Supports MPS, work centers, quality checks, and BOM

- Cloud or on-premise options

- India-localized with GST apps and support

- Customizable workflows and automation

- Integrates with CRM & accounting

PROS:

✅Highly customizable and cost-effective

✅Large community and open-source flexibility

✅Good for lean operations

CONS:

❌Advanced features require paid add-ons

❌ Limited support for complex manufacturing

❌Requires technical expertise for customization

Frequently Asked Questions

1. Why is a specific ERP needed for manufacturing?

Manufacturing has unique needs like BOMs, production scheduling, and quality control. A specialized ERP handles these better than generic systems.

2. Is cloud-based ERP suitable for manufacturing?

Yes, it’s scalable, accessible, and cost-effective. But on-premises may be better for strict security or poor internet.

3. What is the cost of implementing an ERP system for manufacturing?

Costs vary widely—from a few thousand to hundreds of thousands—based on business size, customization, and vendor.

4. How long does it take to implement a manufacturing ERP system?

Implementation timelines can vary from a few months to over a year, depending on complexity of the project, chosen system, extent of customization and business readiness.

15. How do I choose the right ERP system for my manufacturing business?

Know your needs, set goals, compare vendors, check features and costs, and involve key decision-makers.