Introduction:

In today’s fast-paced and competitive trade environment, keeping up an organized and beneficial work environment is basic for success. One outlined procedure that has picked up far off coming to certification for satisfying this objective is the 5S strategy. Starting from Japanese practices, the 5S methodology may perhaps be approach to work environment organization, emphasizing cleanliness, coordinate, and discipline. the 5S strategy is basic for everyone to utilize. It doesn’t require any specialized examination and can be executed all comprehensive in all sorts of companies amplifying from making plants to all work situations, little businesses to huge multinational organizations — and in both private and open divisions This article will facilitate you through the execution of the 5S method to form a more organized and advantageous workplace.

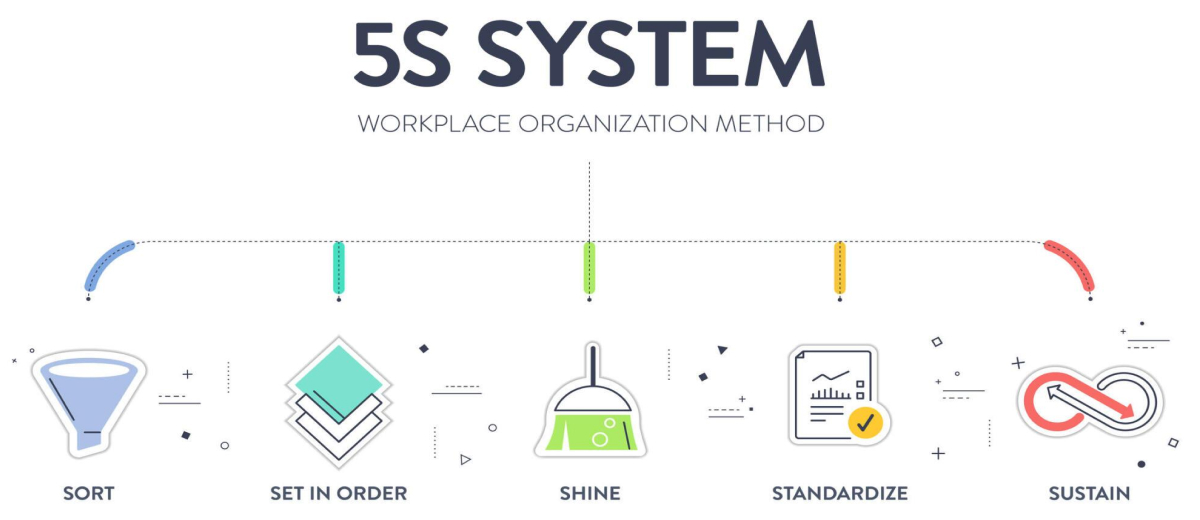

Understanding the 5S Methodology:

The 5S strategy is accumulated from five Japanese words: Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Each “S” talks to a particular step and guide to get prepared of organizing a working environment more productive and efficient.

- Sort (Seiri):

The basic step in actualizing the 5S procedure is to sort through everything in the work environment and detached necessary items from unnecessary ones. Energize specialists to recognize and clear any things that are not significant for their day by day assignments. This makes a qualification in decluttering the workspace, making a more competent and centered environment.

Illustrations of Sort?

- Eliminate waste from your workspace.

- Discard broken or old parts.

- Recycle materials and papers.

- Distinguish everyday tools from those reserved for special cases.

- Prevent workspace overcrowding by avoiding excess materials

- Create a surge area away from the workspace.

- Straighten (Seiton):

Once pointless things are cleared, the another step is to organize the remaining things in a coherent and competent way. Assign a designated place for each item and clearly label the things. This lessens the time went through attempting to discover or materials, driving to progressed productivity.

Illustrations of straighten?

- Provide each item with a unique designated location.

- Utilize colour to organize and convey significance.

- Incorporate shadow boards and other visual cues on the plant floor.

- Allocate another surface or area exclusively for work activities.

- Shine (Seiso):

Ordinary cleaning and back are fundamental to preserve a key to prevent accumulation of dirt and waste. Motivate operators to keep their workstations clean and develop up a cleaning schedule. This not only enhances the overall appearance of the workspace but as well contributes to a more secure and more beneficial working environment.

Illustrations of Shine?

- Inspect the wear and tear on your tools.

- Disassemble larger objects to assess the condition of their components.

- Investigate any recurring dirty spots or messes.

- Ensure adherence to appropriate cleaning procedures to avoid equipment damage

- Standardize (Seiketsu):

Standardizing the processes guarantees consistency and proficiency in each day operations. Make and actualize standardized work practices , visual signals, and checklists to protect the organized state wrapped up through sorting, setting in organize, and shining. This step makes a establishment for maintained improvement.

Illustrations of Standardize?

- Document your 5S procedures.

- Develop checklists for both implementation and audits.

- Compile kits with the necessary materials for specific tasks.

- Incorporate photos and other straightforward visuals into your training materials.

- Establish a task schedule.

- Sustain (Shitsuke):

Sustainability is a key to the long-term triumph of the 5S strategy. Create a culture of nonstop advancement by continually checking and improvising the built up measures. Provide training to new employees and conduct audits to guarantee that the 5S measures are properly applied.

Illustrations of Sustain?

- Conduct regular follow-ups post initial training.

- Instruct employees on conducting 5S audits.

- Address errors with supplementary training.

- Promote open and constructive communication between supervisors and operators to enhance 5S implementation.

- Establish quarterly reminders for auditing the red tag holding area.

Benefits of Implementing the 5S Methodology:

Improved Efficiency: By eliminating clutter and optimizing work processes, employees can complete tasks more efficiently

More Safety: A well-organized workspace diminishes the chance of mischances and wounds, contributing to a more secure working environment.

Improved Morale: A clean and organized working environment moves a positive and centered talk about, boosting master resolve and satisfaction.

Enhanced Safety: A well-organized workspace reduces the risk of accidents and injuries, contributing to a safer working environment.

Improved Customer satisfaction: Progressed productivity and quality coming around from the 5S strategy can lead to advanced client satisfaction.

Conclusion:

The 5S strategy gives a organized and sensible approach to making an organized and productive working environment. By actualizing the measures of sorting, setting in organize, shining, standardizing, and sustaining, organizations can achieve improvements in capability, security, and in common agent fulfillment. Embrace the 5S methodology as a transformative tool for creating a workplace that not only meets but exceeds organizational goals.

Author

Gautham . G

A curious mind always seeking new knowledge, I’m passionate about exploring the world and deciphering the intricacies of finance. My writing reflects a blend of intellectual curiosity and financial acumen.